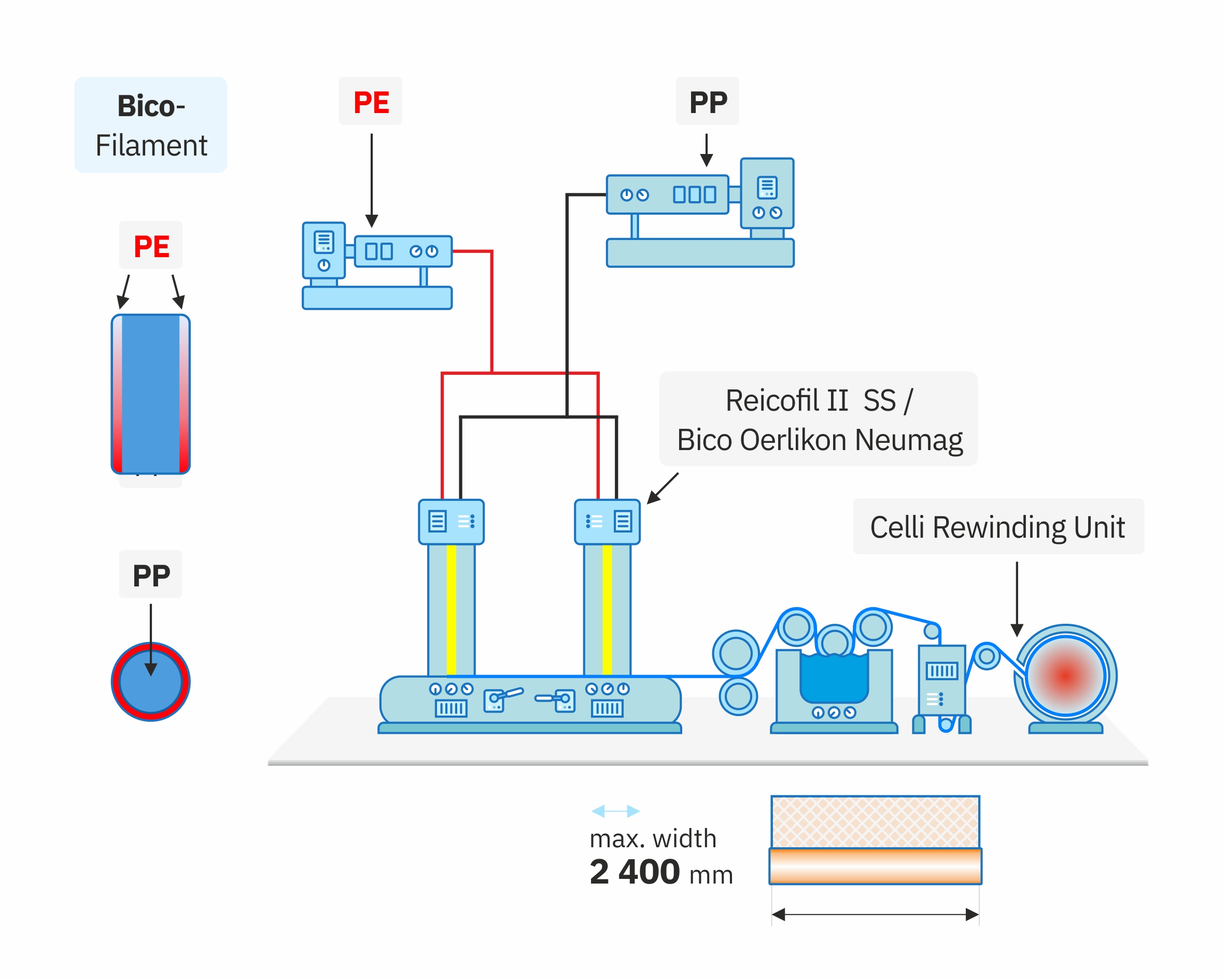

Due to the advanced BICO Technology, we are able to combine different polymers during the fiber formation.

The core and coating of the filament fiber can be made of different raw materials managed by the coordinated operation of the two extruders – and the customers’ needs can be fulfilled in a high quality by dosing specific additives to these materials.

Bico – Nonwoven

Filaments can be created in mono or bico mode. In mono mode, the filaments are single-layered and can be made from a single raw material, using e.g. either polypropylene or polyethylene polymers and some additives.

However, in BICO mode, we are able to form a thin coating around the core of the filaments. The base material of this coating can differ from the core, or it can also be made of a base polymer modified with additives but identical to the core’s material. With our technology, the coat of the filament fibers can be produced from five types, while the core from two types of base polymers. With the help of additional additives, we can produce such a nonwoven product that meets every industrial requirement.

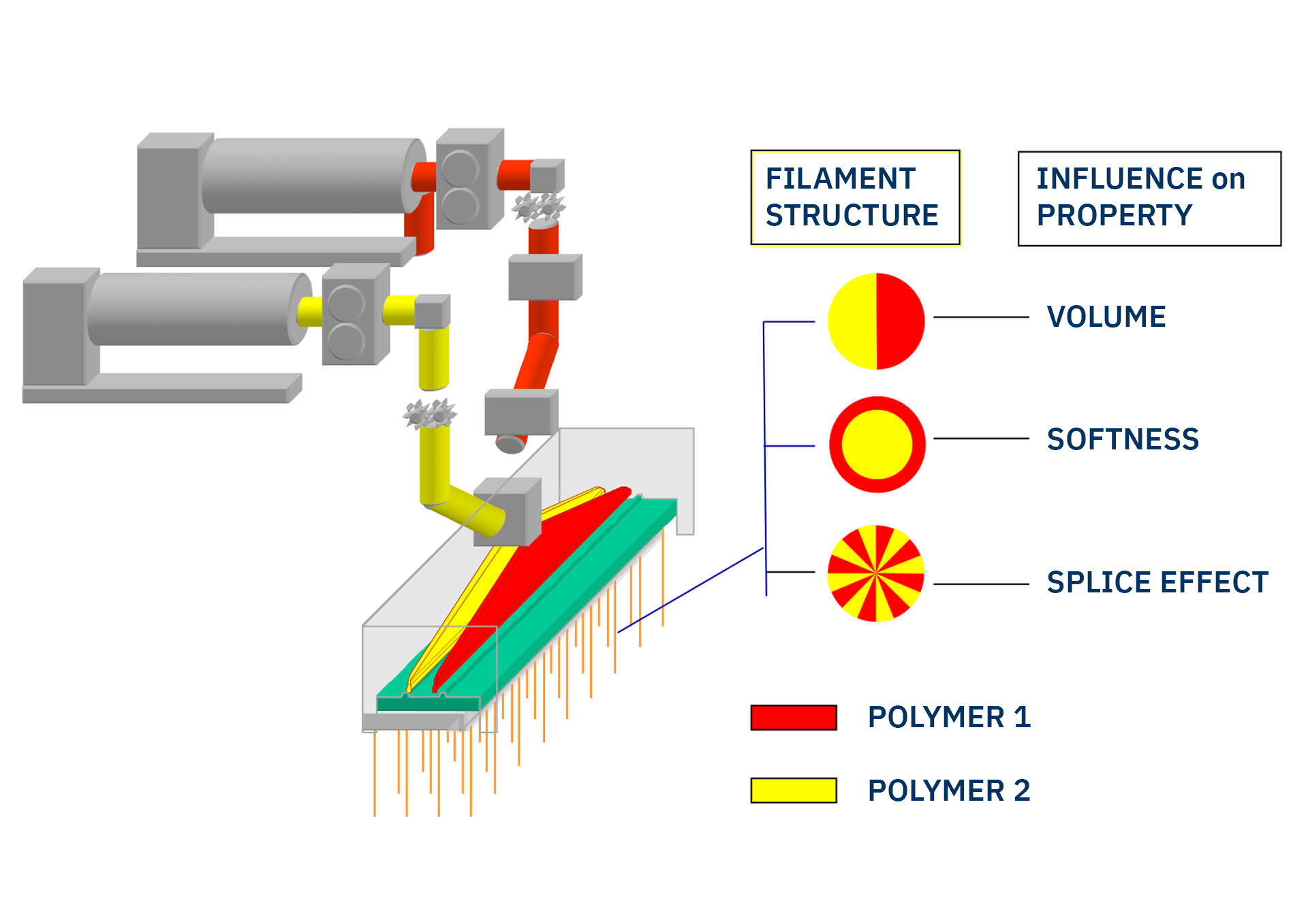

Bico – Technology

The BICO Technology provides further opportunities to adjust the properties of the nonwoven products. The production volume and the material properties can be adjusted by the settings of the filament structure. Output can be increased and we are able to make a softer filament struture or bond the polymers at the material level through the filament structure settings.

Bico Spunbond

The structure of the filament fibers produced by the BICO Technology is clearly visible on electron-microscopic image. The filaments consist of a core (93%) and a coating (7%). In case the filaments are produced in BICO mode, the chemical resistance as well as the mechanical and physical properties of nonwoven products can be better controlled.