The unique LINOPORE know-how (protected by an international trade mark) is a result of the combined use of special technical solutions. Due to their outstanding mechanical properties, multilayer nonwoven products made by LINOPORE process can be used among others in the additional conversion of healthcare and construction product solutions.

Linopore

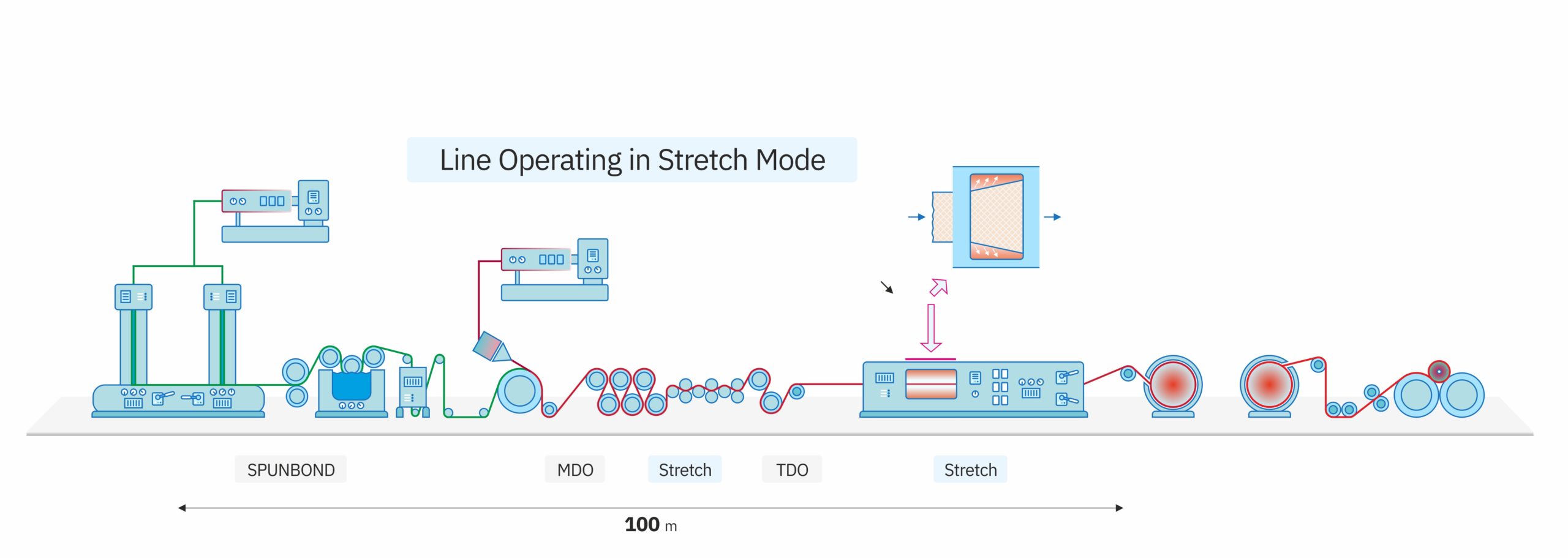

In-line biaxial stretching (up to 5.2 m width): During biaxial stretching, the machine stretches the material simultaneously both in the machine and cross-machine directions until it reaches a production width of 5,200 millimeters. The special properties of the multilayer nonwoven products can be significantly enhanced by this special process.

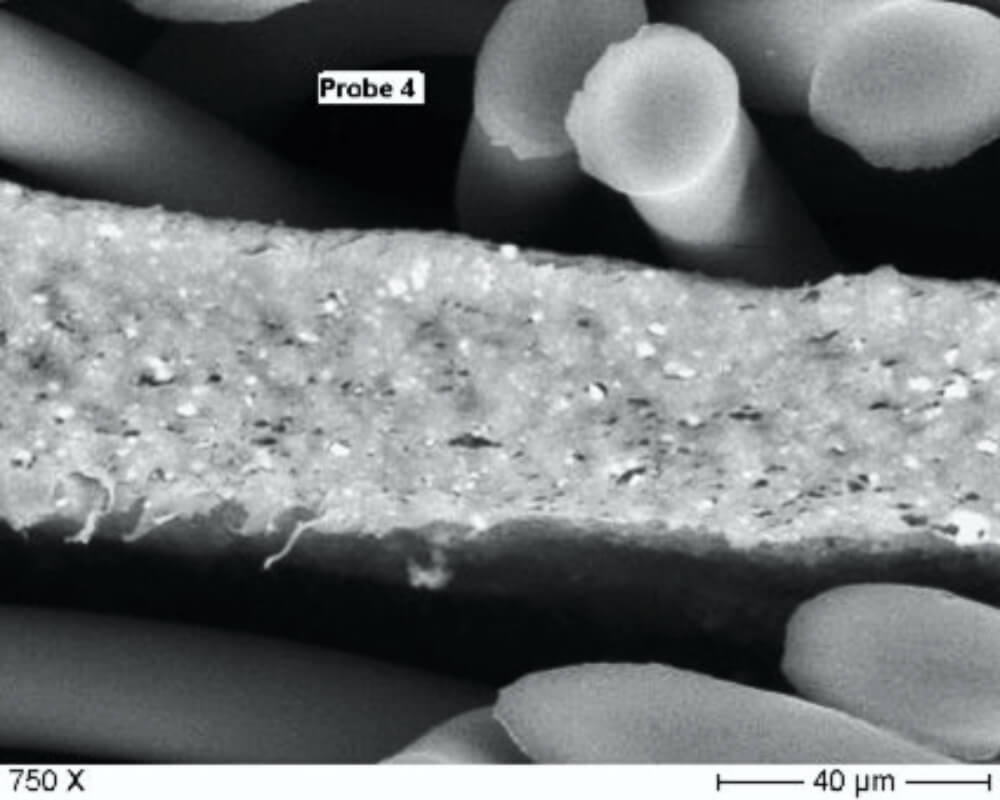

For the LINOPORE multilayer materials, the film extrusion takes place inline during the manufacturing process. The hot and formable film layer is extruded directly on the nonwoven layer while passing through the calendar rollers. The hot layers are bonded to each other at a material level, granting a very stable cohesion of the material layers.

The Inline manufacturing process is ensured by a surveillance system of 9 cameras.

Line Operating in Stretch Mode

LINOPORE™, our special product

A special multi-layer material made of polypropylene nonwoven laminate and breathable film. LINOPORE ™ products are characterized by extra tensile strength, textile appearance and adhesion. Its excellent properties, such as dust and water tightness, go hand in hand with high air permeability. It is widely used in several industrial areas, for instance in the construction, clothing, healthcare and hygiene sectors.

LINOPORE™ made of PP raw material

Particularly suitable for industrial and construction market use.

Features:

- UV resistance

- Water tightness / Breathability

- Extra tensile strength

- High heat resistance

New Linopore made of PE material

Particularly suitable for constructional, medical, packaging, furniture industrial and ventilation use.

Features:

- UV resistance

- Drip tightness / Breathability

- Extra tensile strength

- Good formability, easy processing

Multi-layer products made with Linopore

THREE LAYERS:

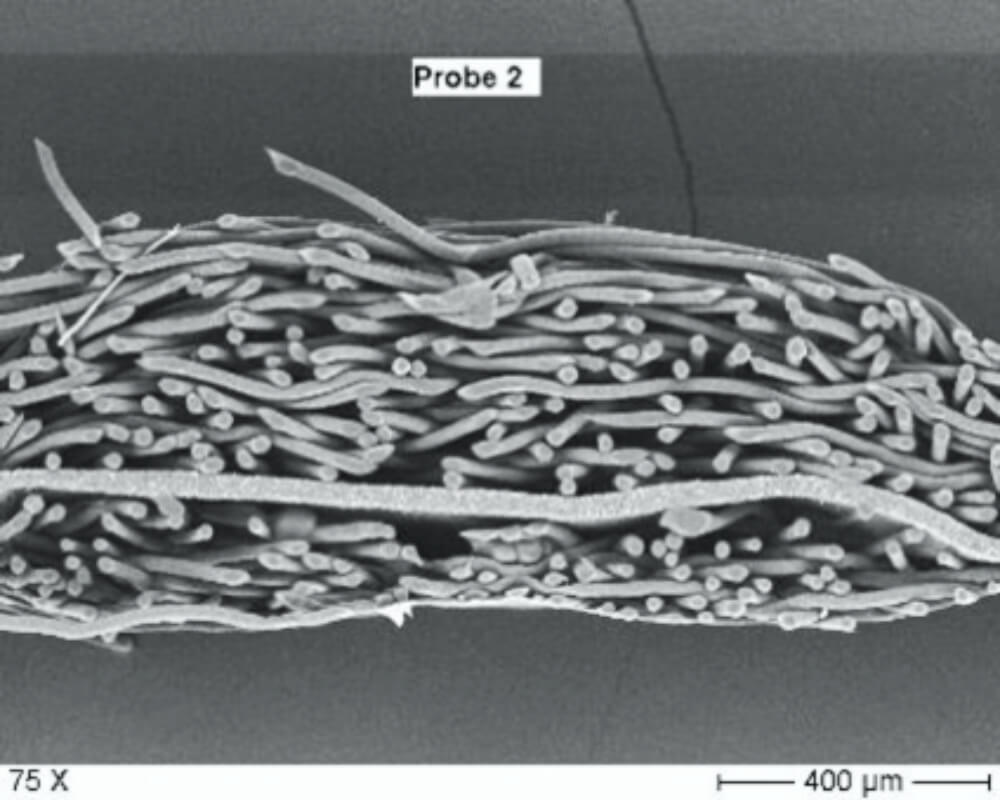

Linopore: PP nonwoven and PP-film laminate

Third layer (Top layer): PP nonwoven. It is thermally bonded to the Linopore material.

Stretched breathable film with CaCO3