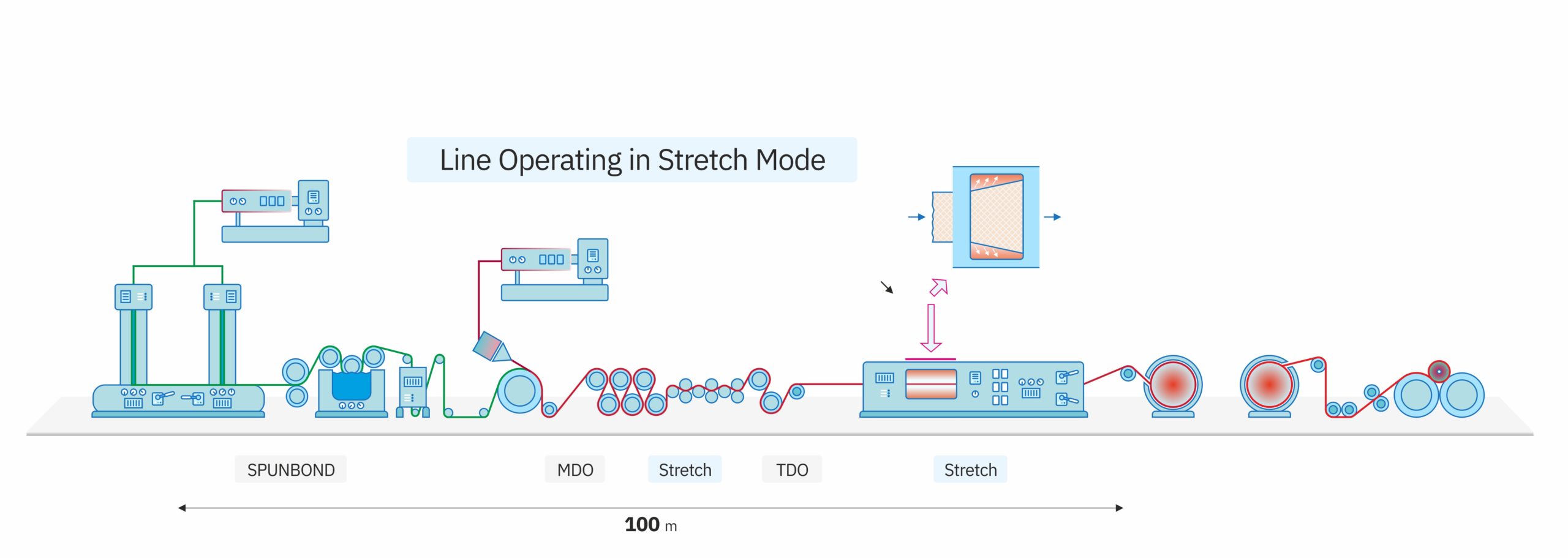

During biaxial stretching, the equipment stretches the material simultaneously in the machine (MD) and cross-machine (CMD) directions until a production width of 5,200 millimeters is reached. The special properties of the multilayer nonwoven products can be significantly enhanced by this process.

In-line biaxial stretching (up to 5.2 m width)

The biaxial stretching makes LINOPORE nonwoven laminate products special. The machine unit starts the process with a nonwoven laminate in a width of 2,400mm and stretches the material in both machine and cross-machine directions until it reaches a width of 5,200 millimeters. The special properties of the products can be significantly enhanced by this process. As a result, the tensile strength of the multilayer laminates produced with the abovementioned technology is much higher than those made with traditional technologies, leading to a major technical product advantage for most industrial applications.

Cast film capability for in-line production of composites

The film extrusion of multilayer composite materials takes place inline during the manufacturing process. The hot and formable film layer is extruded directly on the nonwoven layer passing through the calendar rollers. The hot layers are bonded to each other at a material level, granting a very stable cohesion of the material layers.

In our production process, the continuous quality control is ensured by a surveillance system of 9 cameras.

Line Operating in Stretch Mode