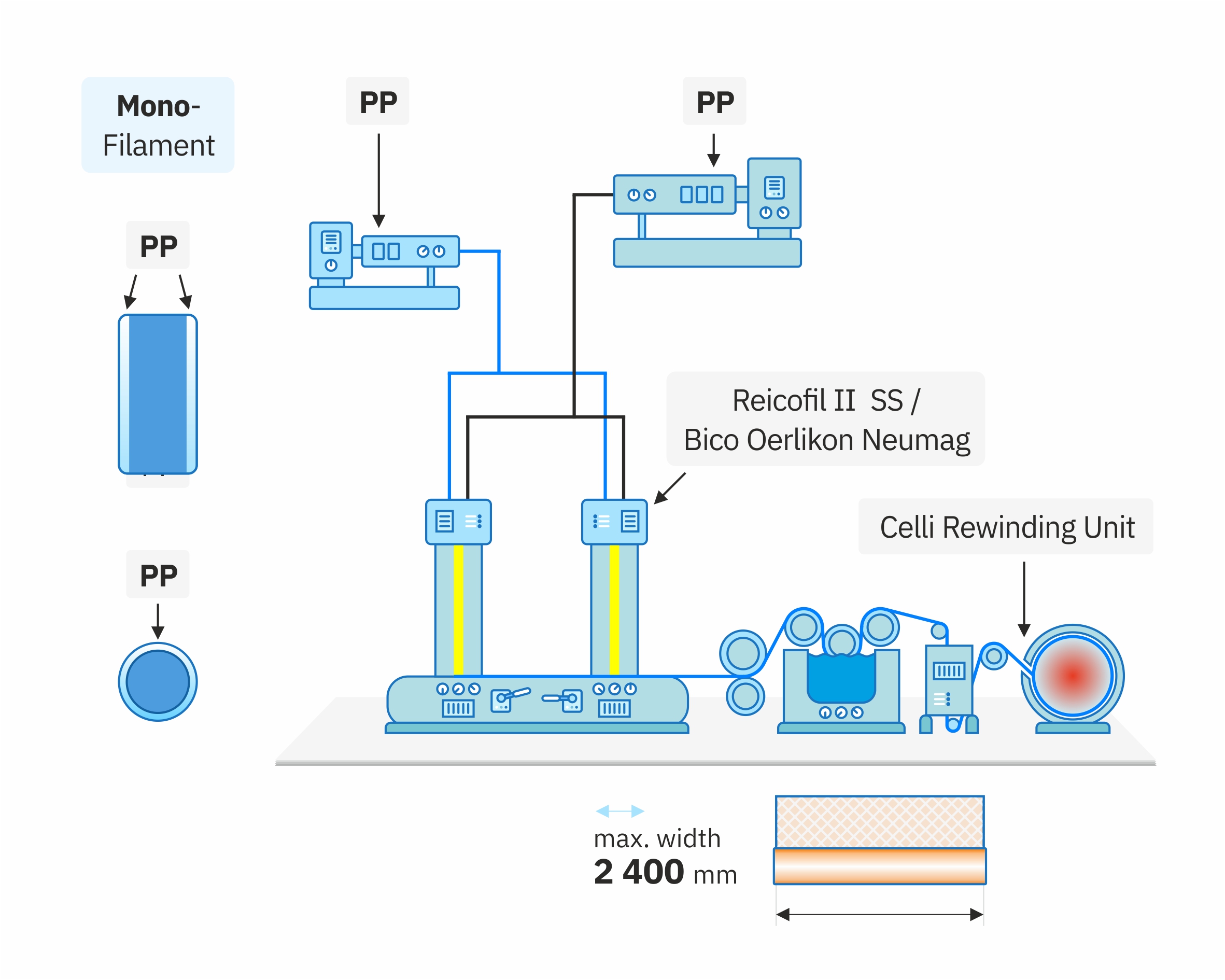

Increased production performance but consistent product quality. The extruded filament fibers are poured onto a conveyor belt by 2 spinning beams with the help of vacuum, where the material reaches its 2.4 meter production width after passing through the calendar rollers.

By using 2 spinning beams, higher production volume and better quality can be achieved. The even distribution of the filament fibers in the material is ensured by the rotation of the beams, the filaments mix and stick to each other, resulting nonwoven products with better physical properties.